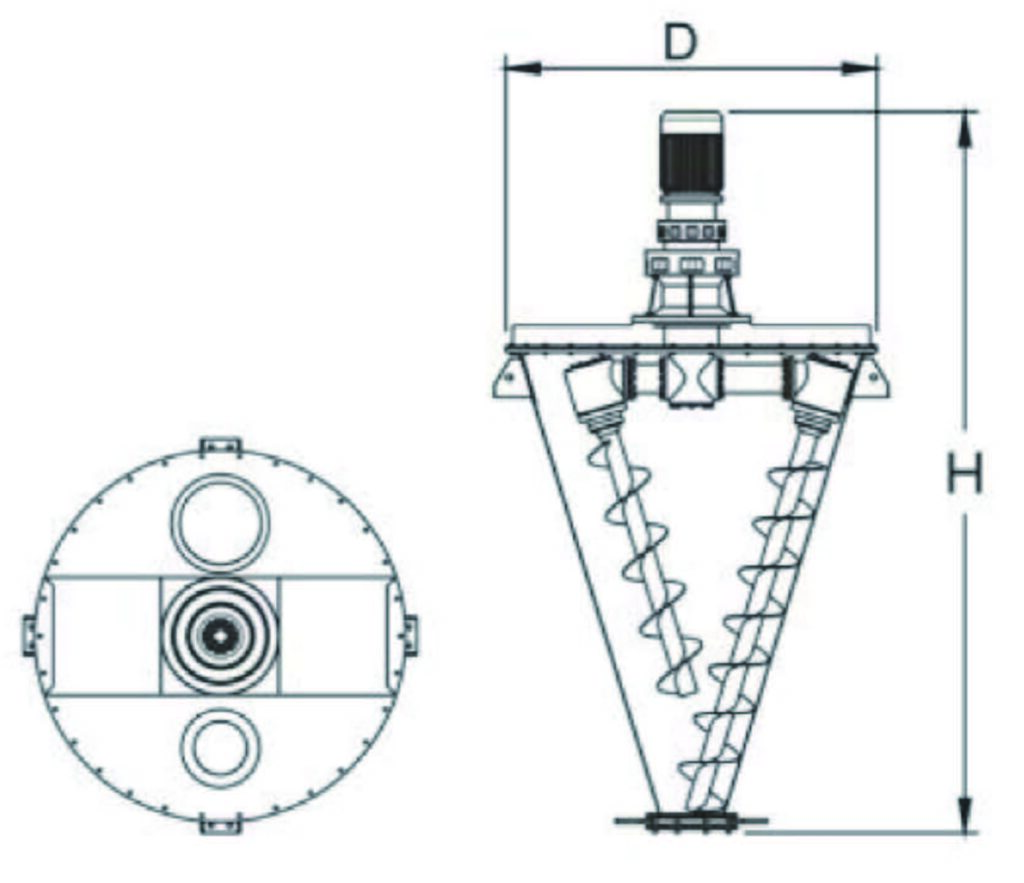

Conical screw mixer (natuta mixer)

Product view

Conical screw mixer (natuta mixer)

Related Articles, Mixing Technology and Resources

How the conical screw mixer (natuta mixer) works

Material in the conical inner vessel can be completely discharged. Gentle mixing does not damage fragile materials such as crystals. The stirring effect of low energy consumption is more suitable for the chemical reaction of materials. Arc structure of the upper cover avoids the dead corners of sanitary cleaning. Equipped with a spherical discharge valve, the discharge is more thorough, stable and convenient.

The stirring parts of the Conical Screw Mixer are two asymmetrical spirals; while they rotate around their own axes (rotation), they also make planetary motion (revolution) around the central axis of the conical container, which along the inner wall of the conical container; The equipment repeatedly lifts the material by the spiral movement and rotation, and produces compound motions such as shearing, convection, and diffusion in the cone, so as to achieve the purpose of uniform mixing.

The total volume of Conical Screw mixer is 0.3-30 m³, the processing capacity of each batch is 0.1-15, m³, and the mixing time is 15-60 minutes.

Applications

Conical Screw Mixer is suitable for mixing powder and powder, granule and powder, powder and liquid. It is widely used in chemical, dye, pigment, pesticide, medicine, plastic and auxiliary industries. It has wide adaptability to mixtures, does not overheat heat-sensitive materials, maintains the integrity of granular materials, and is suitable for the mixing of coarse powder, fine powder, fibers or flake material.