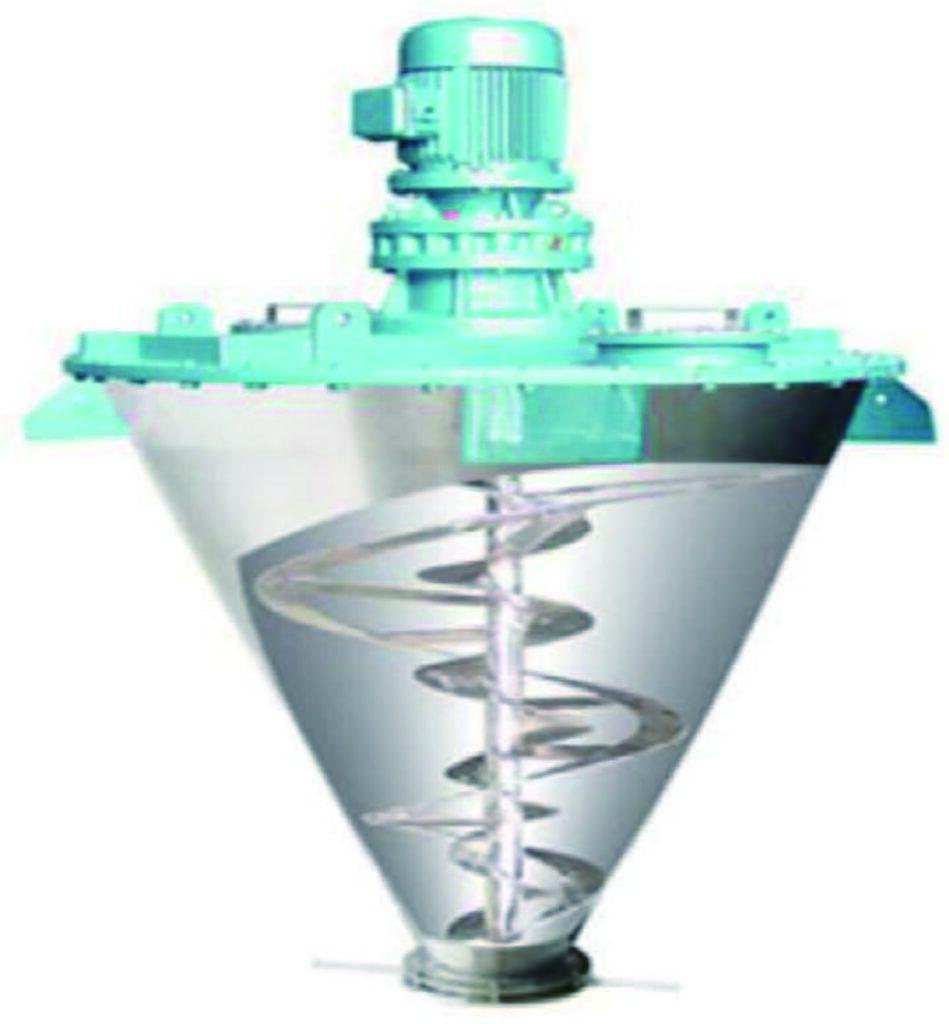

Conical Ribbon Mixer

Product view

Conical Ribbon Mixer

Related Articles, Mixing Technology and Resources

How the Conical Ribbon Mixer works

Driven by the screw and the outer spiral belt, the mixed material moves up and down and circularly in the vessel, so as to achieve a high standard of mixing uniformity. According to different materials, the middle forward or reverse spiral and the outer continuous or broken ribbon can be selected to form the stirring component.

It can mix easy-flow materials gently and completely, and a large amount of materials can be mixed in a short time .

Made of cantilever shaft structure, the bearing end is not in contact with the material. The gap between the stirring paddle and the container wall is very small to prevent the material from sticking. Standardized stirring drive box to ensure stable operation and low maintenance cost.

It can be designed as vacuum or with pressure; Cone can be equipped with hot and cold interlayer; Standard packing seal, skeleton seal, and mechanical seal; Discharge valve can be optional ball valve, Butterfly valve, gate valve; It can be equipped with a liquid spray device, and a chopping device can be added, which can chop polymers of any size to meet the process requirements.

Applications

Conical Ribbon mixer is widely used in the mixing and stirring of various powders, granular materials, slurries or viscous bodies. It can be equipped with liquid spraying system, and can be made into vacuum state, pressurized state, heating or cooling and other process conditions according to user requirements. It can meet various process conditions of material mixing and stirring.